MATEX PLANETARY GEAR REDUCER

Design Example

- Home

- PRODUCTS

- MATEX PLANETARY GEAR REDUCER

- Design Example

DESIGN EXAMPLE

- Power Tools

- Differential Mechanism

- Mortar Roller

- Geared Motor

- Industrial machine drive

- Step-less reduction gear

- Differential gear

- Winch

- Built-in type speed reduction unit

- Built-in input type speed reduction unit

- Liner motion actuator

- Movable center core type gear head

- High speed-up gear / High reduction gear

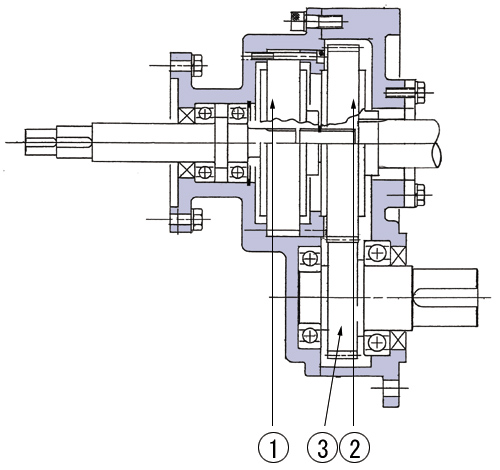

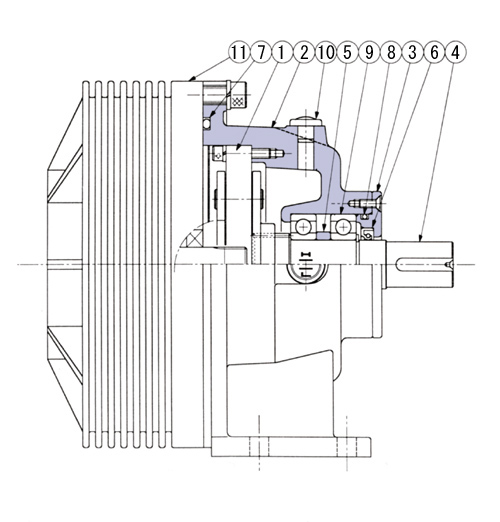

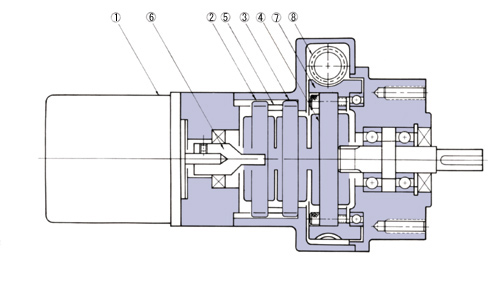

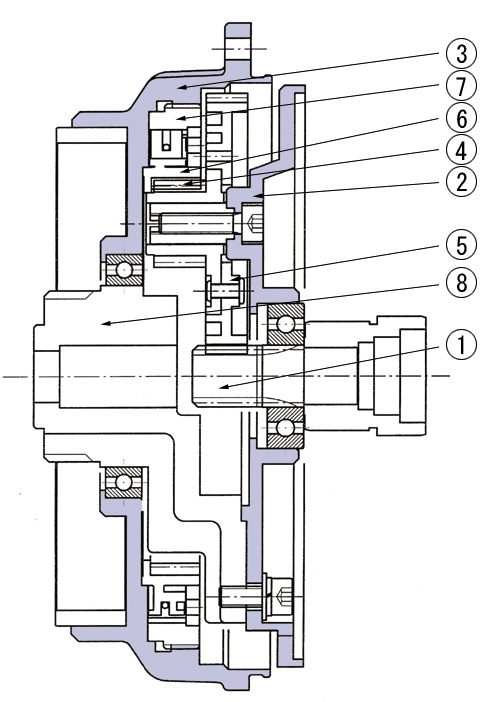

Power Tool

| 1. | Planetary gear units |

| 2. | Planetary gear units |

| 3. | Planetary gear units |

| 4. | Planetary gear units |

| 5. | Spacer |

| 6. | Gear case |

| 7. | Mortar flange |

| 8. | utput shaft |

| 9. | Bearing |

| 10. | Body A |

| 11. | Body B |

| 12. | Mortor |

| 13. | Switch |

- Usage Example

- Electric screw driver, Hand drill, etc.

- Features

-

Compact design for saving space is available with collinear input and output. Multiple reduction ratio is available with combination of various planetary gear unit.

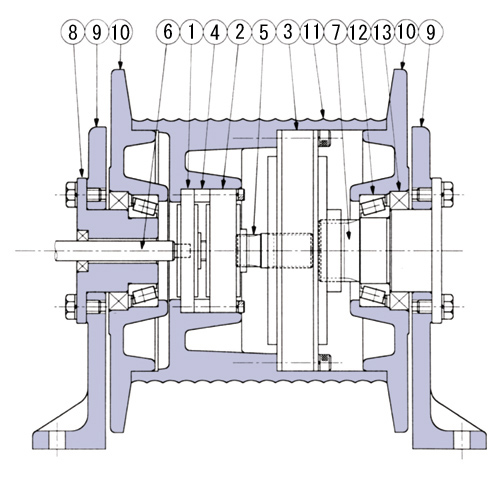

Differential Mechanism

| 1. | Planetary gear unit |

| 2. | Gear case A |

| 3. | Gear Case B |

| 4. | Flange |

| 5. | Shaft N1 |

| 6. | Shaft N2 |

| 7. | Shaft N3 |

| 8. | Thrust bearing |

| 9. | Ball bearing |

| 10. | Ball bearing |

| 11. | Ball bearing |

| 12. | Oil seal |

| 13. | Oil seal |

| 14. | Oil seal |

| 15. | O ring |

| 16. | O ring |

- Usage Example

- Wind power generator

- Features

- This drawing is the planetary gear unit for a wind power generator. Planetary gear units available both for speed up and reduction gears. Input high torque with low speed fan rotation to planetary gear units, and output low torque with high speed revolution power. By revolution coaxial two input shafts in the opposite direction, it is possible to originate higher speeds up ratio.

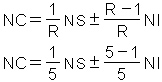

- Rotating ratio of each shaft

- NS=i×NC-(i-1)×NI

i=Reduction ratio

[Example]

When i=4.3 NC=1rpm NI=-1

NS=4.3×1-(4.3-1)×(-1)=7.6

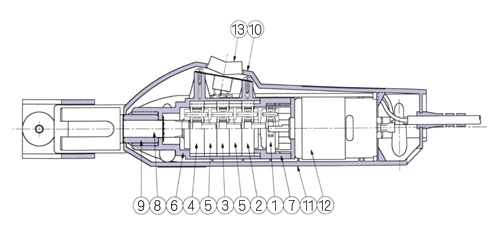

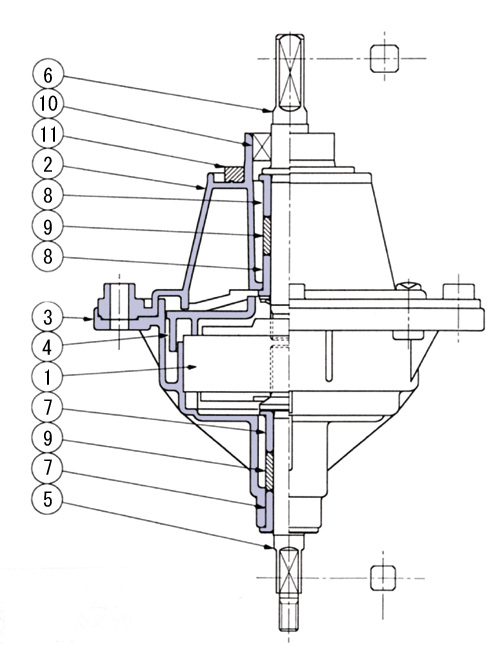

Mortar Roller

| 1. | Planetary gear unit |

| 2. | Planetary gear unit |

| 3. | Spacer |

| 4. | Rotation stopper |

| 5. | Motor |

| 6. | Fix shaft A |

| 7. | Fix Shaft B |

- Usage Example

- Electric massage chair, Window Shatter, Electric vacuum parts, etc.

- Features

- By building mortar and planetary gear units in the body of revolution, saving space is possible. Since all input and output shaft is in the same axle, this product is less vibration.

Geared Motor

| 1. | planetary gear units |

| 2. | Gear case |

| 3. | Oil seal retainer |

| 4. | Output shaft |

| 5. | Bearing spacer |

| 6. | Oil seal |

| 7. | O ring |

| 8. | O ring |

| 9. | Ball bearing |

| 10. | oil cap |

| 11. | Motor |

- Features

- Combine various planetary gear units, it is possible manufacture various ratio gear heads in accordance with the intended use.

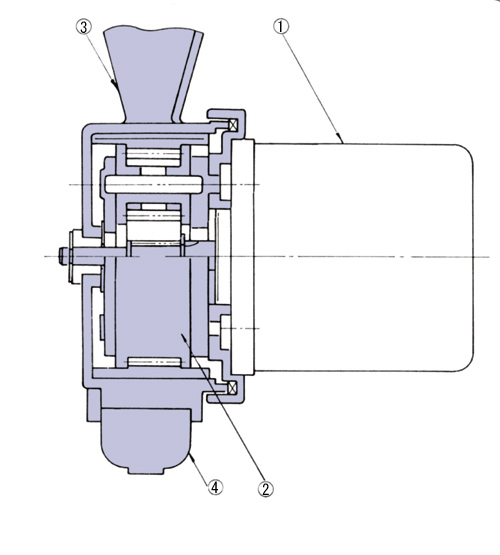

Industrial machine drive

| 1. | Motor |

| 2. | Planetary Gear unit |

| 3. | Fan |

| 4. | Tire |

- EX. Reduction Ratio 1/5

-

NI=Output revolution (rpm)

NS=Input revolution (rpm)

- Usage Example

- Motorized wheels, winch, automatic door, etc.

- Features

- Motor spindle and axle designed on the same axle. Compact designed and individual wheel controllable with building reduction gear units in a wheel house.

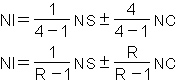

Step-less reduction gear

| 1. | Motor |

| 2. | Servo motor |

| 3. | Planetary Gear Unit |

| 4. | Planetary Gear Unit |

| 5. | Spur gear |

| 6. | Output shaft |

- EX. Reduction ratio 1/4

- NI=Output revolution (rpm)

NS=Input revolution (rpm)

NC=Carrier revolution (rpm

- Usage Example

- Conveyer, etc.

- Features

- Distinctive drive with two input points to planetary gear units by drive motor side and control motor side. Smooth, equable rotating, and transmission with generating differential bi increasing and decreasing of control motor revolution. Rotating shift of direction of output revolution, control of output revolution, and switching of output points are available with switching of input point aims adjustment of input revolution to planetary gear unit.

Differential gear

| 1. | Motor |

| 2. | Planetary Gear Unit |

| 3. | Spacer |

| 4. | Joint |

| 5. | Worm wheel |

| 6. | Worm |

| 7. | Worm wheel |

| 8. | Worm |

- EX. Reduction ratio 1/4

- NI=Output revolution (rpm)

NS=Input revolution (rpm)

NC=Internal revolution (rpm)

- Usage Example

- Take-up machine, Winding machine, Paper manufacturing machine, etc.

- Features

- Higher reduction ratio is available with input from two points. Suitable for low-speed revolution with high torque.

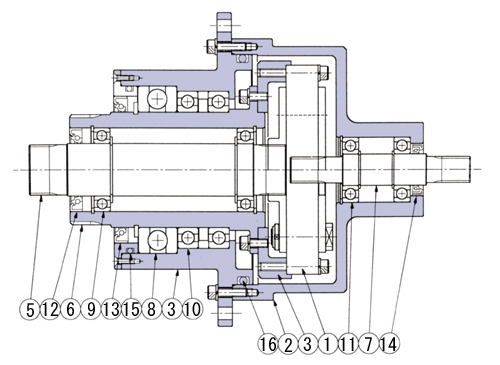

Winch

| 1. | Planetary Gear Unit |

| 2. | Planetary Gear Unit |

| 3. | Planetary Gear Unit |

| 4. | Spacer |

| 5. | Joint shaft |

| 6. | Input shaft |

| 7. | Fix shaft |

| 8. | Input side bush |

| 9. | Side board |

| 10. | Flange |

| 11. | Winding |

| 12. | Cone roller bearing |

| 13. | Oil seal |

- Rotating ratio

- i3=Reduction ratio in the first stage

i2=Reduction ratio in the second stage

i3=Reduction ratio in the third stage

- Usage Example

- Winch etc.

- Features

- Super-high reduction ratio is available with using single motor or source of power from a different gear mechanism. Since the input, output and input of differential are on the same axle, the design is very compact.

Built-in type speed reduction unit

| 1. | Planetary Gear Unit |

| 2. | Upper gear case |

| 3. | Under gear case |

| 4. | Sound-proof cover |

| 5. | Input shaft |

| 6. | Output shaft |

| 7. | Bearing of input shaft |

| 8. | Bearing of output shaft |

| 9. | Felt |

| 10. | Seal |

| 11. | Rubber packing |

- Usage example

- Laundry machine drive, etc.

- Features

- By converting the planetary gear unit with a sealed case, this stricture aims for noise reduction and water proofing. By using gear case as a shaft, also available to extend this kind of model to motor direct drive system.

Built-in input type speed reduction unit

| 1. | Input small gear |

| 2. | Flange |

| 3. | Drum |

| 4. | Planetary gear unit |

| 5. | Large gear |

| 6. | Internal gear |

| 7. | Ratchet gear |

| 8. | Fix flange |

- Usage example

- Electric assist bicycle drive

- Features

- This shows planetary gear units of electric assist bicycle drive. By working out periphery of internal gear, it is easy to bring planetary gear unit with ratchet mechanism.

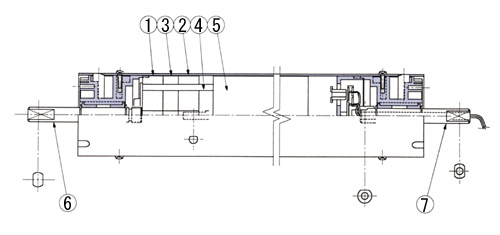

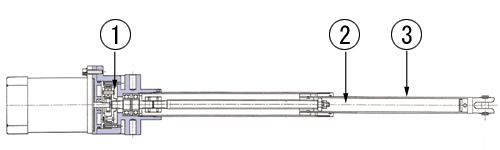

Liner motion actuator

| 1. | Planetary gear unit |

| 2. | Lead screw |

| 3. | Cylinder |

- Usage example

- Electric bed for care, electric reclining chair, etc.

- Features

- It is possible to change reduced revolution over back-and -forth motion through collinear liner shaft. You can get necessary thrust in accordance with reduction ratio by using appropriate combinations of various planetary gear units. It is possible to change reduced revolution over back-and -forth motion through collinear liner shaft. You can get necessary thrust in accordance with reduction ratio by using appropriate combinations of various planetary gear units.

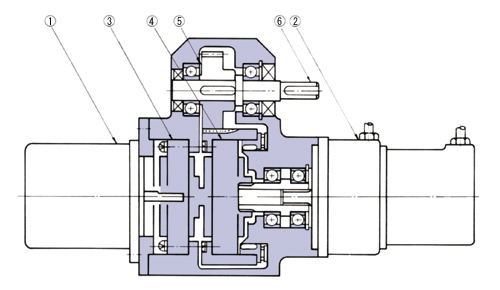

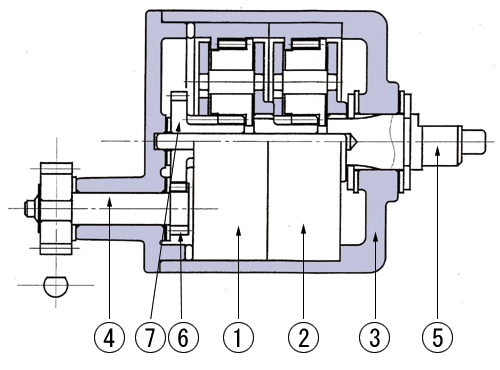

Movable center core type gear head

| 1. | Planetary gear unit |

| 2. | Planetary gear unit |

| 3. | Gear case |

| 4. | Input shaft |

| 5. | Output shaft |

| 6. | Small gear |

| 7. | Large gear |

- Features

- It is to move input shaft by combining spur gear with input side of planetary gear unit. This structure is for circumventing feature of planetary gear unit as input-output is on the same axle.

High speed-up gear / High reduction gear

| 1. | Planetary gear unit |

| 2. | Planetary gear unit |

| 3. | Spur gear |

- Features

- Attach external gear to periphery of internal gear and combine with other spur gear. It realizes high speed up or high reduction using two input points to planetary gear unit.