QUALITY CONTROL SYSTEM

OUR ADVANTAGES

- Home

- OUR ADVANTAGES

- QUALITY CONTROL SYSTEM

STRICT QUALITY CONTROL SYSTEM UNDER ISO9001 & ISO/TS16949(IN CHINA FACTORY)

Matex acquired ISO 9001 and ISO 14001 certifications from early on and established strict quality control systems in all our factories in Japan, Philippines, and China.

In our Chinese factory, in addition to ISO 9001 and ISO 14001, we acquired ISO/TS16949, which is an ISO technical specification aimed at the development of a quality management system for automotive industry, and it enables us to improve products quality continuously, prevent from defects, reduce the quality variation and ensure eliminations of waist in all supply chain. Matex is making all efforts to provide products with higher quality and reliability.

Three factories always share the latest information and any support related to quality issues is always available among three of us.

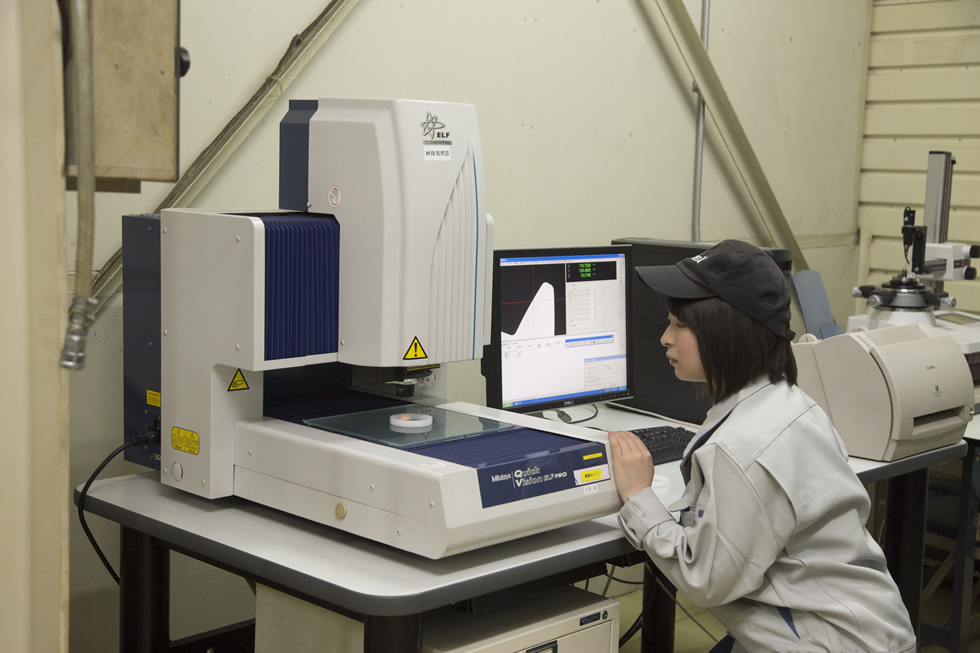

CNC Coordinate Measuring Machine

It measures large items and objects with complexed shape precisely. It also measures basic elements such as distance and angle, furthermore, there-dimensional shapes such as coaxiality, flatness and cylindrical degree can also be evaluated by calculation.

CNC Vision Measuring System

Since this machine is non-contacts type, it can measure products with fine shape or soft materials that might be deformed by contact type measuring system.

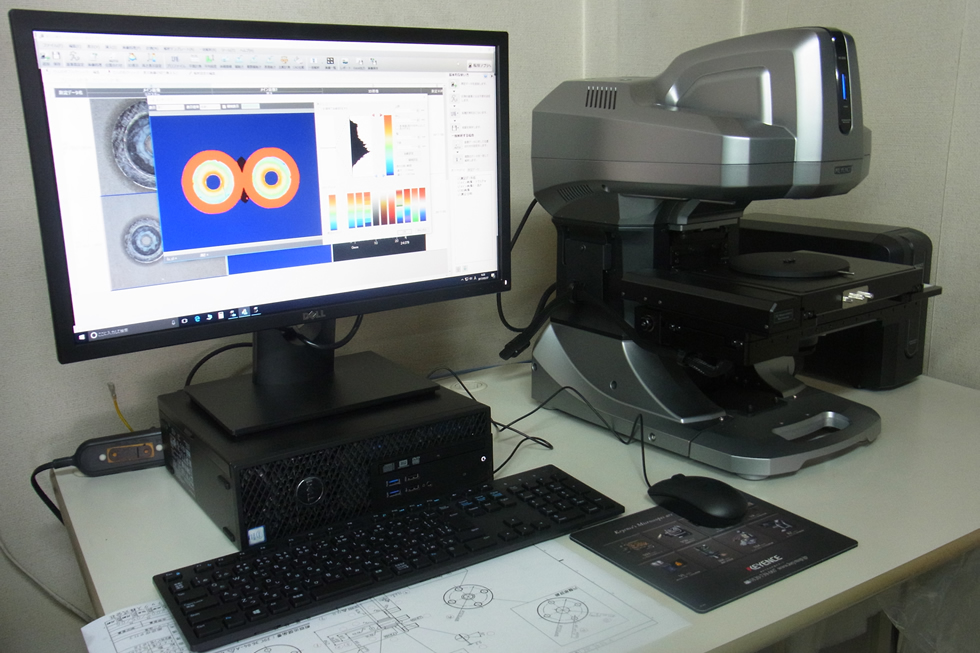

3DMeasuring Systems

It is a non-contact 3D measuring systems with high-accuracy using telecentric lens. This system allows to measure items with high accuracy to the micro level regardless of operator skills. Additionally, as it is non-contact type, it allows to measure the surface roughness without damaging the objects which are made of soft or delicate scratch-prone materials.

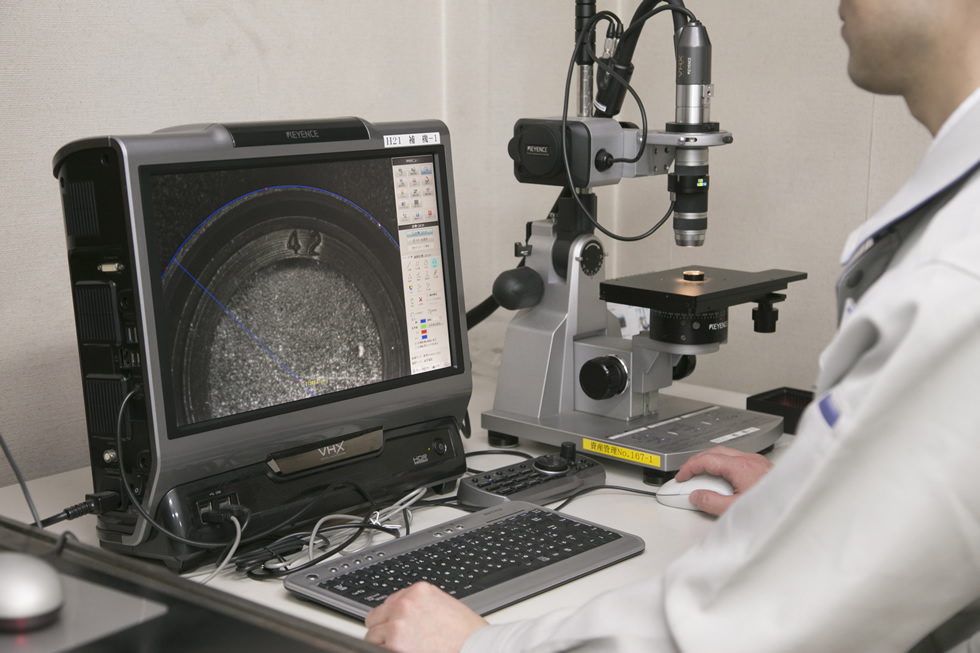

Microscope (Digital Microscope)

Instead of eyepiece, it is equipped with the a camera in order to project magnified images on the monitor. Unlike normal scope, it allows us to observe and measure objects easily on the monitor.

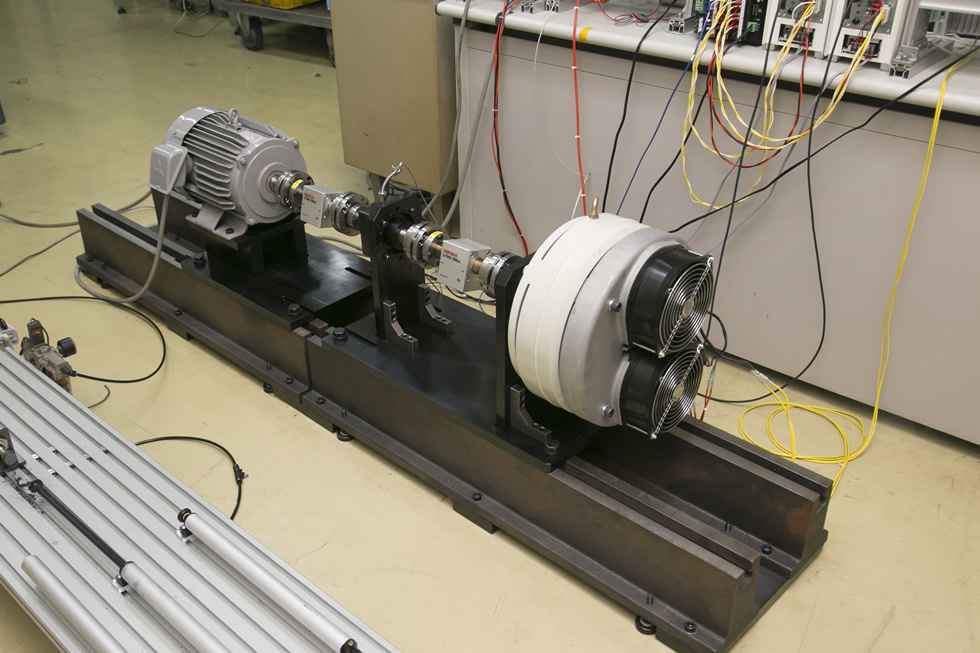

INSPECTION AND EVALUATION SYSTEMS FOR GEAR AND REDUCER

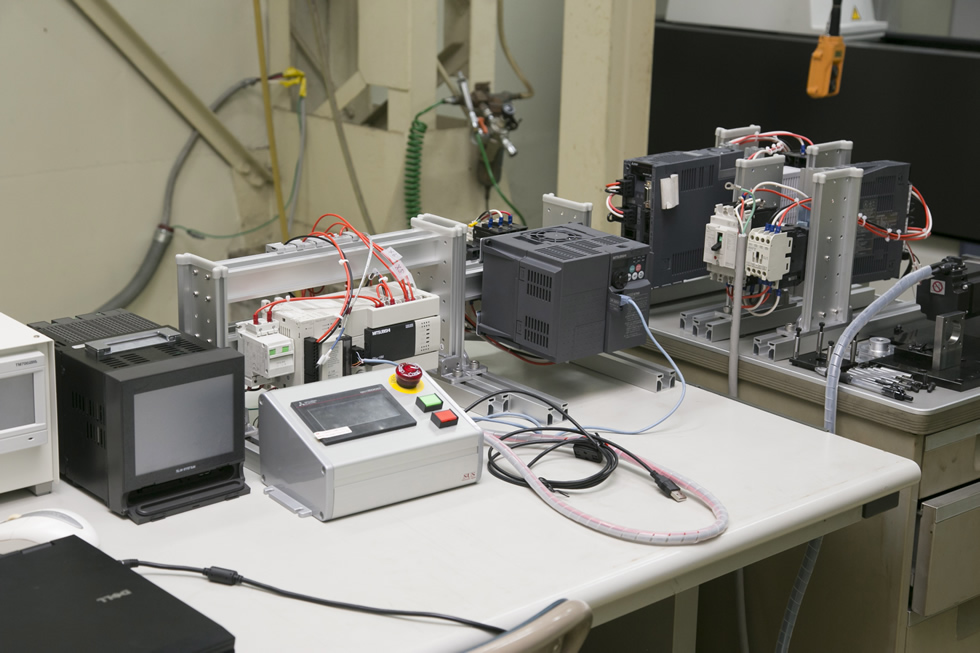

We design and manufacture in-house testing or evaluation devices for our planetary gears, various drive units and electric actuators. And we always put an effort to achieve higher reliability of our products design by various tests such as endurance, life and verification tests.

Tests or inspections can be performed for not only development stage but also mass production upon customers' requests. Operation checking after assembly, destruction test or test measurement are just examples.

Gear Durability Testing Machine

Gear Testing Machine

Control Devise for Gear Durability Testing Machine

Noise measurement room / Tensile Strength and Compression Test Machine

Circularity Measuring Equipment